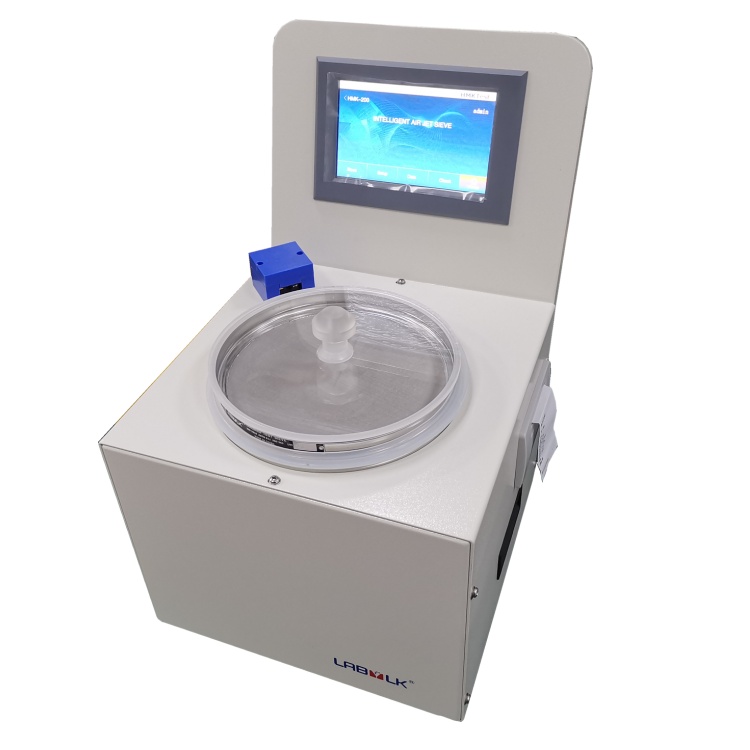

LABULK 0335 Tapped Density Tester︱Tap Density Tester︱Tapped Density Analyzer︱Tapped Density Meter

- PRODUCT DETAIL

- DATASHEET

- PICTURERS

- DOWNLOAD

- TAPPED DENSITY

- Applications

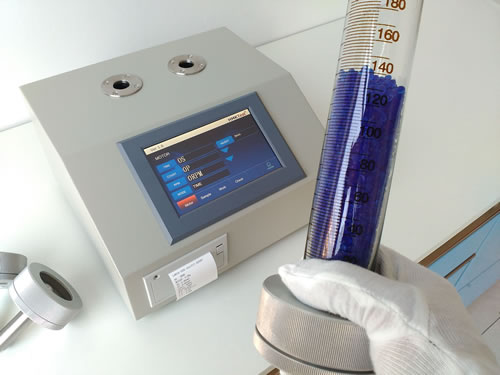

Tapped Density Tester LABULK 0335 measures Tapped Density. In addition it gives Hausner ratio (Tapped Density/Bulk Density) and Compressibility Index ((Tapped Density – Bulk Density/Tapped Density) x 100). AimSizer’s Tap Density Tester is used to measure the tapped density of bulk powders, as well as granulated or flaked materials by standardized and repeatable procedures. AimSizer Tap Density Testers are divided into LABULK 335 Intelligent Tap Density Tester and AS-100 Economic Tapped Density Tester . LABULK 0335 conforms to all international standards such as USP Chapter <616> Method 2 , ASTM B527(metallic powders), ISO 3953(metallic powders), and Ph.Eur. Chapter 2.9.15 ASTM D4164 (formed catalysts), ASTM D4781 (fine catalysts), ISO 787-11 (pigments), ISO 8460 (instant coffee), ISO 8967 (dried milk) and ISO 9161 (uranium oxide powder)etc. Please note that traditional AS-100 Tap Density Tester has been upgraded to LABULK 0335 Intelligent Tap Density Tester, price unchanged.

- 335pic

- 335pic

- 335pic

DATASHEET

SPECIFICATIONS

- Physical Property to measure: tap density/tapped density, Hausner ratio(HR), Compressibility Index(CI)

- Tapped density in grams per mL

- Sample Loading Volume: standard 5-250 mL or as per request

- Timing range: 0-99,999 sec(freely set)

- Counting range: 0-999,999 sec(freely set)

- Tap height: 3 or 14 mm

- Frequency: 250/300(or any data)

- Measurement: W33 x D 31 x H 23 cm (Cylinder excepted)

- Power: 220V/110V/50/60Hz

- RS-232 connection to electric balance

- Test results output by integrated printer

- Internal Database save test results

- Login as Admin or User by password

FUNCTIONS

- Measure tap density of bulk powders

- 110/220V and plug available as per request

- Timed working, automatically stop at set time

- Double work stations, two samples are tested at the same time

- Appearance is exquisite, light weight and size, reasonable structure for easy maintenance

- Tap height adjustable from 3 up to 14 mm to meet all standards

- Meet accuracy and precision requirement of pharmaceuticals

- Login either as Adminstrator or User. Only Admin can modify the setup, GMP compliance. NEW !

- Test reulsts are saved to Database for record, GMP complicance. NEW !

- New generation of operating system, control the operation by 7” LCD precisely

- Automatic communication check between host and modules and host and accessories.

- Alternative testing mode, tap time or number freely set

- Tap density tester calibration such as Tap height selection, being printed on the test report

- In addition to default frequency, user can freely set any rpm to meet special requirement

- In addition to tap number, user can freely set any tap number to meet special requirement.

- During test all the set parameters are visible to understand and evaluate working conditions

- RS-232 connects host and balance, weight number automatically shown on LCD

- Simply a touch to print reports in very detail

- Flowability such as Hausner ratio or Compressibility are obtained during measure tap density

PRINCIPLE

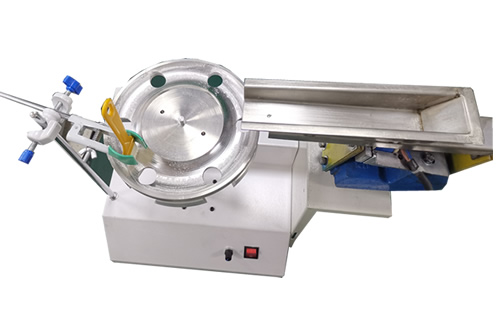

Definition of tapped density is an increased bulk density attained after mechanically tapping a container containing the powder sample (tap density testing machine). Tapped density is obtained by mechanically tapping a graduated measuring cylinder or vessel containing a powder sample. After observing the initial powder volume or weight, the apparatus measuring cylinder or vessel is mechanically tapped, and volume or weight readings are taken until little further volume or weight change is observed. The mechanical tapping is achieved by raising the cylinder or vessel and allowing it to drop under its own weight a specified distance by either of three methods as during tapping may be preferred to minimize any possible separation of the mass during tapping down. This parameter is very important in packing the material. During tapping of the sample, the smaller particles try to fit themselves in gaps of the larger particles and hence the total volume of the powder reduces.Tapped density is achieved by mechanically tapping a measuring cylinder (i.e. raising the cylinder and allowing it to drop a specified distance under its own weight) containing the sample under test.

PICTURERS

- 335pic

- 335pic

- Vanderkamp Tap Density Tester Model 10700

DOWNLOAD

TAPPED DENSITY

- 301-52 What physical properties of the material are associated with the tapped density?

- 301-51 The significance of tapped density and tapped density tester

- 301-50 Microcomputer tapped density tester

- 301-49 Powder tapped density tester

- 301-48 What is tapped density meter

- 301-47 Discuss the tapped density of lithium iron phosphate

- 301-46 Difference between compacted density and tapped density

- 301-45 Which are tapped density tester manufacturers in China?

- 301-44 Price offer of tapped density meter

- 301-43 What is the English name-tap density tester?

- 301-42 How to use bulk density meter tapped density meter to measure powder’s bulk density ?

- 301-41 Battery’s tapped density and tapped density meter

- 301-40 Powder tapped density meter

- 301-39 Full automatic compaction packing density meter and tapped density meter

- 301-38 Which manufacturer of tapped density tester is better

- 301-37 Density tester measuring cylinder and tapped density tester

- 301-36 Tapped density of metal and tapped density meter

- 301-35 Vibration frequency of Tapped density tester

- 301-34 Tapped density tester Shandong Bettersize

- 301-33 Tapped density tester three operating position

- 301-32 International tapped density tester

- 301-31 the operation method of tapped density meter

- 301-30 the price of tapped density meter

- 301-29 VanKel Tapped Density Meter

- 301-28 sales of tapped density meter

- 301-27 Powder density meter and tapped density meter

- 301-26 AUTOTAP tapped density meter

- 301-25 Mechanical vibration device of tapped density meter

- 301-24 GBT/21354 General method for the determination of tapped density of powder products

- 301-23 How does the tap density tester mechanical vibration device work?

- 301-22 Tapped density meter Baidu Baike

- 301-21 Tapped density meter and dissolution tester

- 301-20 ISO 8460 determination of instant coffee’s tapped density, and tapped density meter

- 301-19 EN ISO 3953-1997 metallic powders-determination of tapped density-tapped density meter

- 301-18 EN ISO 787-11-1995 general test method for pigments and extender

- 301-17 Standard test method for tapped density of IDF134 milk powder products

- 301-16 ASTM D4781-1994 standard test method for tapped density of mechanical vibration filling of fine catalyst particles and catalyst carrier particles, and tapped density meter

- 301-15 ASTM D4164-2003 standard test method for mechanical vibration density of molding catalyst and catalyst carrier

- 301-14 ASTM B527 standard test method for the measurement of refractory metallic compound powders by a tapped density meter

- 301-13 What is the difference between HMKTest tapped density meter and other tapped density meters?

- 301-12 Domestic and international standards GB/T 5262-2006 and ISO3953 of metallic powder tapped density determination

- 301-11 What are the specifications of the tapped density meter cylinder?

- 301-10 What is the working principle of tapped density meter?

- 301-9 What are the components of tapped density meter?

- 301-8 The price of tapped density meter

- 301-7 Tapped density calculation formula

- 301-6 the definition of tapped density

- 301-5 About tapped density measurement in US pharmacopoeia USP 616

- 301-4 What is the tapped tensity?

- 301-3 Which factors affect the powder bulk density and tapped density tester usp

- 301-2 In the phrase "tap density tester”, what does tap mean?

- 301-1 what kinds of tapping meters does loose density divided into?

Vanderkamp Tap Density Tester Model 10700 - Vanderkamp Tap Density Tester Model 10700

Vanderkamp Tap Density Tester Model 10700 is a discontinued tap density tester.It is predecessor of Agilent Tap Density Tester, VanKel Tap Density Tester or Varian Tap Density Tester. - Tap Density Tester Electrolab

- Tap Density Tester Compare AS-100 and ETD-1020

- EP Chapter 2.9.15

- ISO 3953

- ASTM B527

- ISO 787

- ASTM D4164

- ASTM D4781

- ISO 8460

- ISO 8967

- ISO 9161

- Agilent Tap Density Tester, VanKel Tap Density Tester, Varian Tap Density Tester

- Compacted density and tap density

- Compressibility Index

- How to Measure Tapped Density?

- How to determine the apparent volume by a Tap Density Tester?

- How is the bulk density of a powder determined?

- How to express bulk density

- Hausner Ratio

- In what units tapped density report?

- Measures of Compressibilty Index/Hausner Ratio

- Tap density formula

- Tapped density tester calibration

- Tap density USP

- Tap Density Definition

- USP 616

- What Is Tap Density?

- What Is Bulk Density Divided Into?

- What Does TAP Mean In a Tap Density Tester?

- What factors afffect bulk density?

Applications

- Powder flowability studies

- Determine pack sizes by determining the amount of settlement during transit

- Density measurement of Pharmaceuticals(Compressibility Index, Hausner Ratio), Minerals, Pigment, Metal Powders and Compounds, Catalysts, Coffee, Tea, Compounds and other powders suitable to be tested according to above mentioned international standards.

- Tap density tester