ASTM B213

- ASTM B212 – ASTB B417 -ISO 4490 -What is Apparent Density

Significance and Use

- The rate and uniformity of die cavity filling are related to flow properties, which thus influence production rates and uniformity of compacted parts.

- The ability of a powder to flow is a function of interparticle friction. As interparticle friction increases, flow is slowed. Fine powders may not flow.

- Humidity and moisture content influence flow rate. Wet or moist powders may not flow.

- This test method may be part of the purchase agreement between powder manufacturers and powder metallurgy (P/M) part producers, or it can be an internal quality control test by either the producer or the end user.

Scope

- This test method covers the determination of the flow rate of metal powders and is suitable only for those powders that will flow unaided through the specified apparatus.

- The values stated in SI units are to be regarded as the standard (except for the flowmeter funnel, which is fabricated in inch-pound units). The values given in parentheses are for information only.

- This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Index Terms

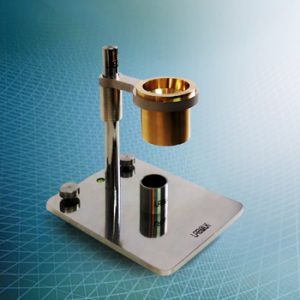

Instrument Manufacturer

- Aimsizer Scientifc PTE LTD. is a leading and reliable supplier of Hall Flowmeter and Carney Funnels in the world. All the metallic parts are processed and supplied by our qualified subcontractor in order to make the instrument accurate and robust to meet the user’s requirement.

Automatic Hall flowmeter https://www.aimsizer.com