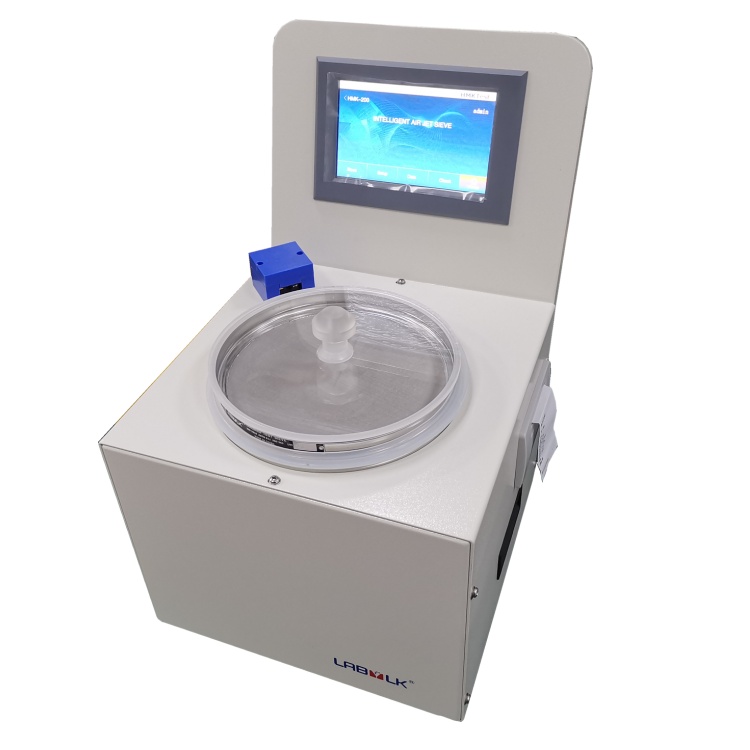

HMK-200 Intelligent Air Jet Sieve is a more advanced air jet sieving machine compared to the standard model AIR-200, while maintaining the same hardware specifications as the standard version. It utilizes the power of air jets to analyze the size limits and particle size distribution of powders and is also used for efficiently separating and filtering powders. The HMK-200 is composed of a sieve plate, nozzle, standard test sieves, transparent cover, sieving control and analysis system, undersieve sample collector, vacuum cleaner, among other components. Its features, similar to the standard model, include short sieving time with high efficiency, less likelihood of sieve clogging, effective elimination of agglomeration and static electricity, and a sieving lower limit of up to 3 microns. In addition, the intelligent model offers an additional sieve-opening function, where the nozzle repeatedly sweeps the sieve holes to further reduce the probability of clogging. Besides automatically calculating the oversize percentage available in the standard model, it can also calculate the undersize percentage and interval percentage. The sieving results can be printed and compared with standard results for storage. The instrument comes equipped with over 200 pharmaceutically relevant standard operating procedures (SOPs) and offers unlimited data storage and export functionality. It complies with ISO 4610, ASTM D5158, the European Pharmacopoeia (EP), and the United States Pharmacopeia (USP) standards.

SPECIFICATIONS

- Operating System: Intelligent Screening Control Analysis System

- Speed: 18 RPM adjustable

- Size Range: 3-5000 μm

- Repeatability: <1%

- Accuracy: <1%

- Negative Pressure: -10 to 0 KPa

- Timer Range: 0-9999 minutes 59 seconds

- Dimensions: L35 x W35 x H58 cm / 14.8 kg

- Power Supply: 110-220V / 50-60Hz / 70W

PRINCIPLE

The instrument uses an electronic vortex generator. With the assistance of the vacuum, the negative-pressure air vortex generated by the air jet sieving machine drives the powder through the nozzle, where it rises and collides with the transparent cover. The powder with eliminated agglomerates is then re-absorbed by the vortex into the standard test sieve according to particle size. Smaller particles pass through the sieve and are collected in the sample collector, while larger particles remain on top of the standard test sieve. The residue on the collection sieve is weighed on an electronic balance, and the weight is entered into the software, which automatically calculates the percentage of powder retained on the sieve and outputs the result through the built-in thermal printer.