- PRODUCT DETAIL

- PICTURES

- SPECIFICATIONS

- APPLICATIONS

- HARDWARE

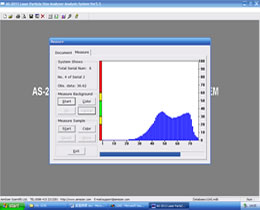

- SOFTWARE

- SCHEMATICS

AS-2011 is a Laser Diffraction Particle Size Analyzer working with principle of Mie Scattering to precisely determine the particle size distribution from 0.1 to 500 micrometer. This equipment has a few advantages all its own.Robust laser diode and innovative photocells optimize the precision of static light scattering and give AS-2011 a longer operational lifetime. Patented optical bench uproots light path deviation, one of the major technical problems in the industry of particle size analysis.User-friendly program and advanced algorism bring accuracy and repeatability qualification to International Standard ISO13320-1 Particle Size Analysis – Laser Diffraction Methods.Laser particle size analyzer price is usually expensive however AS-2011 has become the most reliable and cost-effective (particle size analyzer price) laser diffraction particle size analyser being widely used in Particle Characterization.

PICTURES

SPECIFICATIONS

- Measurement Principle: Mie Scattering Theory/Laser Diffraction Principle, same principle as Mastersizer 2000/3000

- Size Range: 0.1-500 micrometer ( particle size D50, D03, D06, D10, D16, D25, D75, D84, D90, D97, D98 etc. )

- Repeatability: <1%

- Accuracy: <1%

- Light Source: Semiconductor Laser Diode as long as 25,000 hrs

- Measurement Time: <60 seconds

- Power: 220V/110V 50/60Hz 80W

- Data Connection: RS-232

- Operating Systems: Windows

- ISO Norms: ISO 13320

APPLICATIONS

- Particle size distribution such as Median D50, D03, D06, D10, D16, D25, D75, D84, D90, D97,D98 in micron range.

- Abrasives, Adhesives, Agrochemical

- Barite, Batteries, Bentonite, Boron Carbide, Brucite, Bubble

- Calcite, Calcium Carbonate, Carbon Black, Catalysts, Cement, Ceramics, Chemicals, Clay, Coal, Coatings, Corundum, Cosmetics

- Diamond Powder, Dolomite, Diatomite

- Emulsion, Environmental, Explosives

- Ferrite, Flour, Fluorescent, Fluorite, Food & Beverage, Food Additive

- Graphite, Grinding

- Inks, Kaolin

- Medicine, Metal Powder, Mica, Milling, Minerals

- Oxides

- Paints, Paper, Petrochemical, Pharmaceuticals, Pigments, Plaster, Plastics, Polymers

- Quartz

- Refractory, Resins

- Silica, Slurries, Soil Sediments, Starch, Sulfur, Synthetics

- Talc, Toners, Tourmaline

- Wollastonite, Zeolite, Zirconium Silicate etc

HARDWARE

- Special Coating

External (corrosion resistant) and internal (anti-reflective) coatings effectively shield the interference by unwanted light and reflecting walls. Special coating protects the laser diffraction and improves the analyzer performance. - Robust Light Source

Excellent monochromatic laser diode works for at least 25,000 hours. No work, no loss. Monochrome improves the accuracy and long lifetime extends the working life of laser particle size analyzer. A novel technology integrates Fourier lens into the holder of laser diode which optimizes the light path alignment. - Stable Optical Bench

All major optical assemblies such as laser, cell holder and detection system are firmly fixed on one cast steel optical bench. This patented design uproots light path deviation, one of the major technical problems in the industry of particle size analysis. - Sensitive Photocells

High-resolution photocells make AS-2011 much more sensitive than any other particle size analyzer. Detection system array effectively captures the scattered light thus ensures the authenticity and accuracy of particle size characterization. - High-Speed Circuit Boards

Circuit boards of serial port, filtering, amplification and data transmit & process have a considerable advantage in speed over traditional ones. They work with new algorism to give a satisfactory measurement time. - Versatile Small (Volume) Cell Assembly

The small cell assembly has found wide applications because of its very small fault rate and high reliability. Corrosion-resistant small cell can either hold water or other mediums. Micro silent agitator fully stirs up the suspension and improves the accuracy and repeatability. - Optional AS20 Dispersing Unit

AS20 Dispersing Unit integrates functions of dispersing, agitating and circulating. It effectively suspends high-density particles in water to achieve a better accuracy. The panel of AS20 is simple and easy to use. - Ingenious Cell Holder

Patented cell holder makes the shift between small cell and flow cell assembly easy and safe.

SOFTWARE

- Advanced Mie Scattering

AS-2011 laser particle size analysis system adopts the most advanced principle of Mie Scattering and gives the micron particles a scientific and objective particle size analysis.Theory of particle size analyzer is very important - Accurate & Fast Algorism

A new algorism has been designed which will be able to obtain the accurate results and greatly reduce the measurement time. - Flexible Parameters

In order to improve the correlation capability of AS-2011 with other laser particle size analyzers, AimSizer develops advanced and flexible parameters to make AS-2011 the preferred substitute of world renowned LPSAs. These parameters can provide users with the acceptable correlation results. - Safe Log on

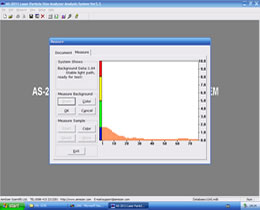

User can log on particle sizing software in two ways: Administrator or Operator, only Administrator is authorized to modify the major settings of particle size analysis system, which greatly improves the security and stability. - Automatic Measurement

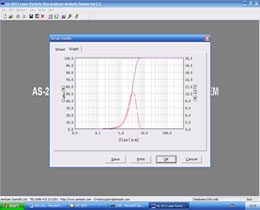

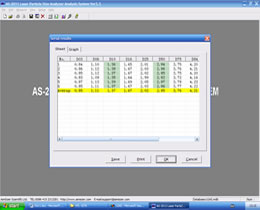

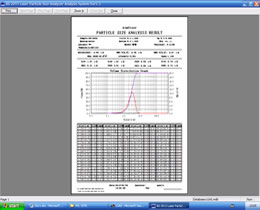

The automation starts with automatic error detecting on background and light path, and then size analysis is carried out automatically. In less than 60 seconds size distribution is displayed on the computer screen ready for exporting to Excel or print. - Comprehensive Analysis report

The result analysis report includes typical values, size distribution curve/histogram as well as table of size distribution in order to compare with other results respectively. Particle size includes D50, D03, D06, D10, D16, D25, D75, D90, D97, D98. User is also allowed to edit and customize the report. - Authoritative Validation & Traceability

Aimsizer validate each unit by measuring stable Certified Reference Material CRM SBC2005, which ensures the performance of each analyzer and optimizes the traceability. The results obtained must agree with the standard values before export. - Satisfying Accuracy & Repeatability

More than meeting the requirement of ISO13320-1 on accuracy and repeatability (<3%), AS-2011 further optimizes the reproducibillity to a new level (<3%)

SCHEMATICS

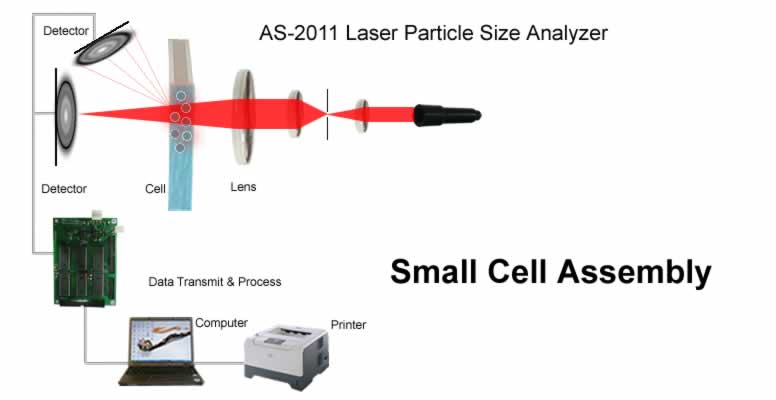

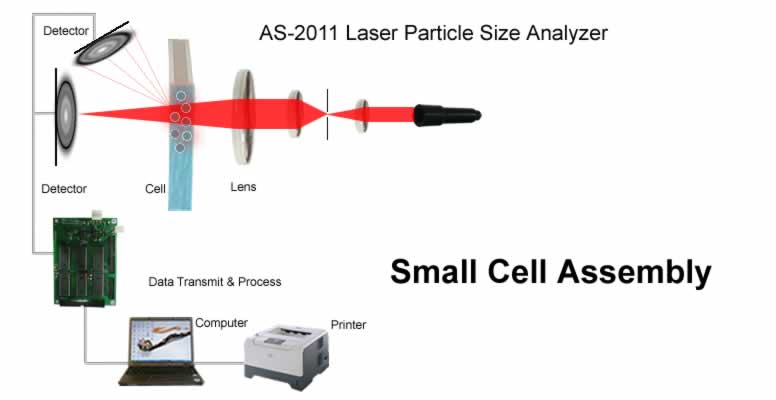

- Small Cell Assembly

Principle/Theory: Small volume cell is also called micro cell. It is a transparent cell usually made of quartz with parallel faces. It is used to hold sample suspension when using static light scattering method to determine the particle size distribution. During test, an inside stirrer moves up and down to suspend the particles. The laser illuminates the particles, then detector collects the diffracted light and the data is transmited and processed, the software calculates according to laser diffraction and Mie Scattering and output the particle size distribution to accomplish the particle size analysis.

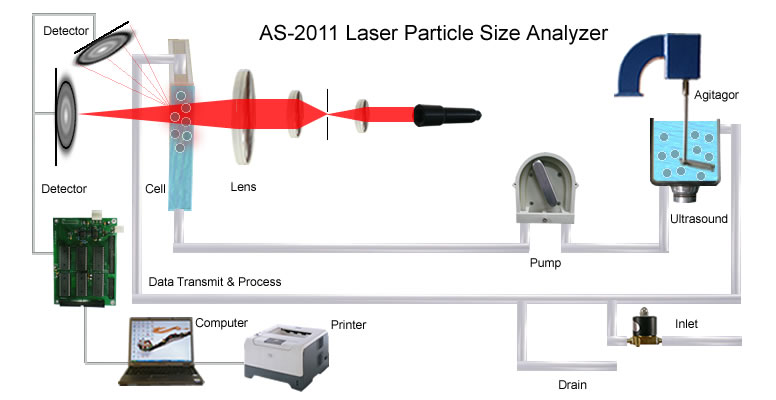

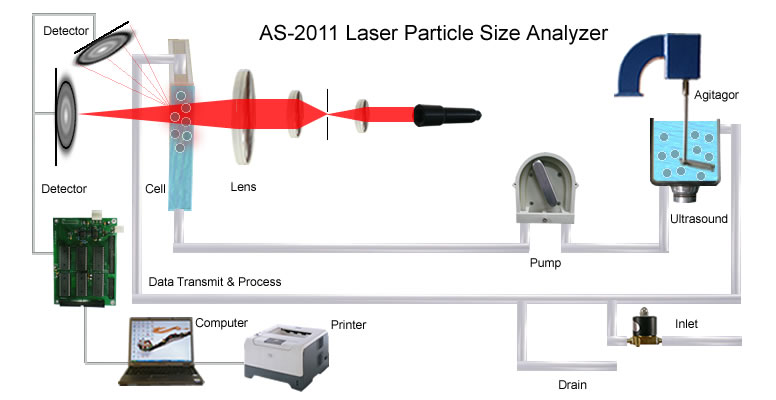

Particle Size Analyzer Principle - Dispersing Unit

Pinciple/Theory: Dispersing Unit is sometime called circulating and dispersing unit. It integrates suspension dispersing and circulation. The dispersion is done by ultrasonic probe attached using special technique to the bottom of the tank.The flow through cell is open both on the top and bottom not like small volume cell, the agitator blends and peristaltic pump sends the fully dispersed (by ultrasonic) particle ensenbles to the flow through cell, the laser is diffracted by the particles and the photocells receive the data and the electric board transmit and process for further particle size analysis in the software.

- http://youtu.be/IffJUQFXAZ8

- http://www.youtube.com/watch?v=5HaO9oXDHoo